316 Stainless Steel Washers

316 Stainless Steel Washers

316 Stainless Steel Washers is a thin plate (typically disk-shaped) with a hole (typically in the middle) that is normally used to distribute the load of a threaded fastener, such as a screw or nut. Other uses are as a spacer, spring (belleville washer, wave washer), wear pad, preload indicating device, locking device, and to reduce vibration (rubber washer). Washers often have an outer diameter (OD) about twice their inner diameter (ID), but this can vary quite widely.

Washers are usually metal or plastic. High-quality bolted joints require hardened steel washers to prevent the loss of pre-load due to Brinellingafter the torque is applied.

Rubber or fiber gaskets used in taps (or faucets, or valves) to stop the flow of water are sometimes referred to colloquially as washers; but, while they may look similar, washers and gaskets are usually designed for different functions and made differently.

Washers are also important for preventing galvanic corrosion, particularly by insulating steel screws from aluminium surfaces.

The origin of the word is unknown; the first recorded use of the word was in 1346, however, the first time its definition was recorded was in 1611.[1]

316 Stainless Steel Washers Suppliers

1) Amco Metals

2) Trychem Metals & Alloys

3) Special Metals

4) Vinay Eningennering Co.

5) Regal Sales Corporation

6) Mahavir Metal Corporation

7) Panche Industries

8) Kanti Enterprises

9) Variety Metal Corporation

10) Sysco Piping Solutions INC

For Promotion Of Your Company Write Your Requirements In The Comment Box And Our Business Manager Will Assist You.

Thanks & Best Regards

Samarpan Thorat

9029137339

9029137339

(Marketing Manger - India)

Type and form

316 Stainless Steel Washers

Washers can be categorised into three types;

- Plain washers, which spread a load, and prevent damage to the surface being fixed, or provide some sort of insulation such as electrical

- Spring washers, which have axial flexibility and are used to prevent fastening or loosening due to vibrations

- Locking washers, which prevent fastening or loosening by preventing unscrewing rotation of the fastening device; locking washers are usually also spring washers.

The American National Standards Institute (ANSI) provides standards for general use flat washers. Type A is a series of steel washers at broad tolerances, where precision is not critical. Type B is a series of flat washers with tighter tolerances where outside diameters are categorized as "narrow", "regular" or "wide" for specific bolt sizes.[2]

"Type" is not to be confused with "form" (but often is). The British Standard for Metric Series Metal Washers (BS4320), written in 1968, coined the term "form". The forms go from A to G and dictate the outside diameter and thickness of the flat washers.

- Form A: Normal diameter, normal thickness

- Form B: Normal diameter, light thickness

- Form C: Large diameter, normal thickness

- Form D: Large diameter, light thickness

- Form E: Larger diameter, normal thickness

- Form F: Larger diameter, normal thickness

- Form G: Largest diameter, larger thickness.[3]

Plain washers

Name(s)ImageDescriptionPlain washer (or "flat washer") A flat annulus or ring, often of metal, used to spread the load of a screwed fastening. Additionally, a plain washer may be used when the hole is a larger diameter than the fixing nut.[4][5]Fender washer (US), penny washer or "repair washer" (UK)

A flat annulus or ring, often of metal, used to spread the load of a screwed fastening. Additionally, a plain washer may be used when the hole is a larger diameter than the fixing nut.[4][5]Fender washer (US), penny washer or "repair washer" (UK) A flat washer with a particularly large outer diameter in proportion to its central hole. These are commonly used to spread the load on thin sheet metal, and are named after their use on automobile fenders. They can also be used to make a connection to a hole that has been enlarged by rust or wear. In the UK, the name originally comes from the size of the old British penny. In the UK, most industries refer to all large OD washers as penny washers, even when the OD is as much as twice the size of the old penny.

A flat washer with a particularly large outer diameter in proportion to its central hole. These are commonly used to spread the load on thin sheet metal, and are named after their use on automobile fenders. They can also be used to make a connection to a hole that has been enlarged by rust or wear. In the UK, the name originally comes from the size of the old British penny. In the UK, most industries refer to all large OD washers as penny washers, even when the OD is as much as twice the size of the old penny.

A large plate or washer connected to a tie rod or bolt. Anchor plates are used on exterior walls of masonry buildings, for structural reinforcement. Being visible, many anchor plates are made in a style that is decorative.[6]Torque washerUsed in woodworking in combination with a carriage bolt; it has a square hole in the centre into which the carriage bolt square fits. Teeth or prongs on the washer bite into the wood, preventing the bolt from spinning freely when a nut is being tightened.[7]

A large plate or washer connected to a tie rod or bolt. Anchor plates are used on exterior walls of masonry buildings, for structural reinforcement. Being visible, many anchor plates are made in a style that is decorative.[6]Torque washerUsed in woodworking in combination with a carriage bolt; it has a square hole in the centre into which the carriage bolt square fits. Teeth or prongs on the washer bite into the wood, preventing the bolt from spinning freely when a nut is being tightened.[7]

A flat annulus or ring, often of metal, used to spread the load of a screwed fastening. Additionally, a plain washer may be used when the hole is a larger diameter than the fixing nut.[4][5]Fender washer (US), penny washer or "repair washer" (UK)

A flat annulus or ring, often of metal, used to spread the load of a screwed fastening. Additionally, a plain washer may be used when the hole is a larger diameter than the fixing nut.[4][5]Fender washer (US), penny washer or "repair washer" (UK) A flat washer with a particularly large outer diameter in proportion to its central hole. These are commonly used to spread the load on thin sheet metal, and are named after their use on automobile fenders. They can also be used to make a connection to a hole that has been enlarged by rust or wear. In the UK, the name originally comes from the size of the old British penny. In the UK, most industries refer to all large OD washers as penny washers, even when the OD is as much as twice the size of the old penny.

A flat washer with a particularly large outer diameter in proportion to its central hole. These are commonly used to spread the load on thin sheet metal, and are named after their use on automobile fenders. They can also be used to make a connection to a hole that has been enlarged by rust or wear. In the UK, the name originally comes from the size of the old British penny. In the UK, most industries refer to all large OD washers as penny washers, even when the OD is as much as twice the size of the old penny.

An archaic form of this washer was sold as a "pot mender", usually in small quantities through a retail ironmonger. This included two washers, a nut and bolt and a sealing washer of rubber, cork or fibre sheet. They could be used for sealing small holes, rust spots or removed pipe connections in water tanks or large cooking vessels.

Spherical washerPart of a self-aligning nut; it is a washer with one radiused surface, which is designed to be used in conjunction with a mating nut in order to allow for up to several degrees of misalignment between parts.Anchor plate or wall washer A large plate or washer connected to a tie rod or bolt. Anchor plates are used on exterior walls of masonry buildings, for structural reinforcement. Being visible, many anchor plates are made in a style that is decorative.[6]Torque washerUsed in woodworking in combination with a carriage bolt; it has a square hole in the centre into which the carriage bolt square fits. Teeth or prongs on the washer bite into the wood, preventing the bolt from spinning freely when a nut is being tightened.[7]

A large plate or washer connected to a tie rod or bolt. Anchor plates are used on exterior walls of masonry buildings, for structural reinforcement. Being visible, many anchor plates are made in a style that is decorative.[6]Torque washerUsed in woodworking in combination with a carriage bolt; it has a square hole in the centre into which the carriage bolt square fits. Teeth or prongs on the washer bite into the wood, preventing the bolt from spinning freely when a nut is being tightened.[7]Spring and locking washers

| Name(s) | Image | Description |

|---|---|---|

| Belleville washer, also known as a cupped spring washer or a conical washer |  | A washer with a slight conical shape, which provides an axial force when deformed. The surface may be serrated, which will have improved locking capabilities.[8] |

| Curved disc spring |  | Similar to a Belleville, except the washer is curved in only one direction, therefore there are only four points of contact. Unlike Belleville washers, they exert only light pressures.[9] |

| Wave washers |  | A washer with a "wave" in the axial direction, which provides spring pressure when compressed. Wave washers, of comparable size, do not produce as much force as Belleville washers. In Germany, they are sometimes used as lock washers, however they are less effective than other choices.[a][10] |

| Split washer or spring lock washer |  | A ring split at one point and bent into a helical shape. This causes the washer to exert a spring force between the fastener's head and the substrate, which maintains the washer hard against the substrate and the bolt thread hard against the nut or substrate thread, creating more friction and resistance to rotation. Applicable standards are ASME B18.21.1, DIN 127B, and United States Military Standard NASM 35338 (formerly MS 35338 and AN-935).[11]

Spring washers are a left hand helix and allow the thread to be tightened in a right hand direction only, i.e. a clockwise direction. When a left hand turning motion is applied, the raised edge bites into the underside of the bolt or nut and the part that it is bolted to, thus resisting turning. Therefore, spring washers are ineffective on left hand threads and hardened surfaces. Also, they are not to be used in conjunction with a flat washer under the spring washer, as this isolates the spring washer from biting into the component that will resist turning. Where a flat washer is required to span a large hole in a component, a nyloc nut (nylon insert) must be used.

The use and effectiveness of spring lock washers has been in debate of late,[when?] with some publications[12][who?] advising against their use on the grounds that, when tight, the washer is flat against the substrate and gives no more resistance to rotation than a normal washer at the same torque. NASA researchers have gone as far as to say "In summary, a lockwasher of this type is useless for locking."[13][14] However, a spring washer will continue to hold the bolt against the substrate and maintain friction when loosened slightly, whereas a plain washer will not.[b]

The benefit of spring lock washers lies in the trapezoidal shape of the washer. When compressed to loads near the proof strength of the bolt, it will twist and flatten. This reduces the spring rate of the bolted joint which allows it to maintain more force under the same vibration levels. This prevents loosening.[15]

|

| Toothed lock washer, serrated washer or star washer[10] |  | A washer with serrations that extend radially inward or outward to bite into the bearing surface. This type of washer is especially effective as a lock washer when used with a soft substrate, such as aluminium or plastic,[10] and can resist rotation more than a plain washer on hard surfaces, as the tension between washer and the surface is applied over a much smaller area (the teeth). There are four types: internal, external, combination, and countersunk. The internal style has the serrations along the inner edge of the washer, which makes them more aesthetically pleasing.[16] The external style has the serrations around the outer edge, which provides better holding power, because of the greater circumference.[17] The combination style has serrations about both edges, for maximum holding power.[18] The countersunk style is designed to be used with flat-head screws.[19]

Tooth lockwashers are also used for ground bonding where a metal lug or object must be electrically bonded to a surface. The teeth of the washer cut through surface oxides, paints or other finishes and provide a gas-tight conductive path. In these applications, the washer is not placed under the head of the screw (or under the nut), it is placed between the surfaces to be bonded. In such applications, the tooth washer does not provide any anti-rotation locking features.[20]

|

| Tab washer |  | A locking washer that works by having a side tab that can be bent into place against a nut. Metallic or non-metallic, the tab washer notch prevents rotation relative to the shaft or fastener. Variations include single, multiple, formed and flat.[21] |

Gaskets

| Name | Image | Description |

|---|---|---|

| Shoulder washer | A plain washer type with integral cylindrical sleeve; they are used to keep separate different metal types, and as seals.[22] This term is also used for electrically insulating grommets.[23] |

Specialised types

| Name(s) | Image | Description |

|---|---|---|

| Keps nut or K-lock nut |  | A nut with an integral free spinning washer; assembly is easier because the washer is captive. |

| Top hat washer | A shoulder washer type used in plumbing for tap fitting. | |

| Insulating shoulder washer | Used to electrically isolate a mounting screw from the surface it secures. Often made of nylon, these are also made of teflon, PEEK or other plastics to withstand higher temperatures. | |

| Keyed washer | A washer with a key to prevent rotation, and is used to lock two nuts in place, without allowing the torque applied to the top nut to cause the bottom nut to also rotate (such as in a threaded headset on a bicycle). | |

| Torque Limiting Washer | A type of washer used in a variety of torque sensitive applications, designed to limit torque to a predetermined level and not beyond. |

Materials

Washers can be fabricated from a variety of materials including, but not limited to:[24]

- Steel – Carbon steel, spring steel, 304 stainless steel, and 316/316A stainless steel

- Metal – Copper, brass, aluminium, titanium, iron, bronze, and zinc

- Alloy – Silicon bronze, Inconel, Monel, and Hastelloy

- Plastic – Thermoplastics and thermosetting polymers such as polyethylene, PTFE (Teflon)[25]

- Nylon – Nylon 6, Nylon 66, Nylatron, and Tecamid MDS[26]

- Specialty – Fibers, ceramics, rubber, felt, leather, bimetals, and mica

Standard metric flat washers sizes

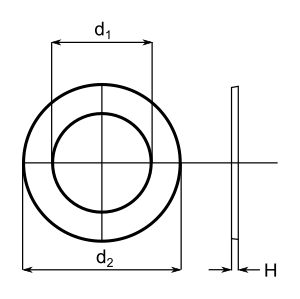

Washers of standard metric sizes are listed in the table below. Measurements in the table refer to the dimensions of the washers as described by the drawing.

| Nominal screw sizes, M (mm) | Screw pitch thread, P (mm) | Diameter (mm) | Thickness, H (mm) | |||

|---|---|---|---|---|---|---|

| 1st choice | 2nd choice | Coarse | Fine | Internal hole, d1 | External, d2 | |

| 1 | 0.25 | 1.1 | 3 | 0.3 | ||

| 1.2 | 0.25 | 1.3 | 3.5 | 0.3 | ||

| 1.4 | 0.3 | 1.5 | 4 | 0.3 | ||

| 1.6 | 0.35 | 1.7 | 4 | 0.3 | ||

| 1.7 | 1.8 | 4.5 | 0.3 | |||

| 1.8 | 0.35 | |||||

| 2 | 0.4 | 2.2 | 5 | 0.3 | ||

| 2.5 | 0.45 | 2.7 | 6 | 0.5 | ||

| 2.6 | 2.8 | 7 | 0.5 | |||

| 3 | 0.5 | 3.2 | 7 | 0.5 | ||

| 3.5 | 0.6 | 3.7 | 8 | 0.5 | ||

| 4 | 0.7 | 4.3 | 9 | 0.8 | ||

| 5 | 0.8 | 5.3 | 10 | 1 | ||

| 6 | 1 | 0.75 | 6.4 | 12 | 1.6 | |

| 7 | 1 | 7.4 | 14 | 1.6 | ||

| 8 | 1.25 | 1 | 8.4 | 16 | 1.6 | |

| 10 | 1.5 | 1.25 or 1 | 10.5 | 20 | 2 | |

| 12 | 1.75 | 1.5 or 1.25 | 13 | 24 | 2.5 | |

| 14 | 2 | 1.5 | 15 | 28 | 2.5 | |

| 16 | 2 | 1.5 | 17 | 30 | 3 | |

| 18 | 2.5 | 2 or 1.5 | 19 | 34 | 3 | |

| 20 | 2.5 | 2 or 1.5 | 21 | 37 | 3 | |

| 22 | 2.5 | 2 or 1.5 | 23 | 39 | 3 | |

| 24 | 3 | 2 | 25 | 44 | 4 | |

| 27 | 3 | 2 | 28 | 50 | 4 | |

| 30 | 3.5 | 2 | 31 | 56 | 4 | |

| 33 | 3.5 | 2 | 34 | 60 | 5 | |

| 36 | 4 | 3 | 37 | 66 | 5 | |

| 39 | 4 | 3 | 40 | 72 | 6 | |

| 42 | 4.5 | 3 | 43 | 78 | 7 | |

| 45 | 4.5 | 3 | 46 | 85 | 7 | |

| 48 | 5 | 3 | 50 | 92 | 8 | |

| 52 | 5 | 4 | 54 | 98 | 8 | |

| 56 | 5.5 | 4 | 58 | 105 | 9 | |

| 60 | 5.5 | 4 | 62 | 110 | 9 | |

| 64 | 6 | 4 | 66 | 115 | 9 | |

| 68 | 70 | 120 | 10 | |||

| 72 | 74 | 125 | 10 | |||

| 76 | 78 | 135 | 10 | |||

| 80 | 82 | 140 | 12 | |||

| 85 | 87 | 145 | 12 | |||

| 90 | 93 | 160 | 12 | |||

| 100 | 104 | 175 | 14 | |||

SAE

316 Stainless Steel Washers

SAE 316L grade stainless steel is a standard for an austenic variety of stainless steel given the American SAE designation "316L" which indicates that this steel is low-carbonsubtype of marine grade stainless steel containing 16-18% chromium, 10-14% nickel, 2.0-3.0% molybdenum, and no more than 0.03% carbon, 2% manganese, 0.75% silicon, 0.045% phosphorus, 0.03% sulphur, and 0.1% nitrogen by weight, with the remainder consisting entirely of iron (by comparison, regular 316 grade may contain up to 0.08% carbon by weight). For many years it was one of the most highly preferred substances for medical devices and implants, but the greater biocompatibility titanium and cobalt-chromium alloys as well as their greater resistance to corrosion have caused 316L to lose favor.[1][2]

|

316 Stainless Steel Washers |

|

316 Stainless Steel Washers |

|

316 Stainless Steel Washers |

|

316 Stainless Steel Washers |

|

316 Stainless Steel Washers |

|

316 Stainless Steel Washers |

Comments

Post a Comment